What can set you apart as a quality manufacturer is your knowledge of specialised equipment used for unique purposes. One such specialised fastener is the socket set screw - it is not widely available with most fastener suppliers.

Getting to understand rare fasteners can help you simplify processes which would otherwise require complex solutions to perform the same action.

What is a Set Screw?

Set screws are used when one component has to be fixed within another one without any protrusions which could decrease the efficiency of the equipment. For example, fastening a gear and shaft assembly with a regular hex bolt might be inefficient as the hex head might cause inconveniences for the smooth operation of the assembly. In such situations, where protrusions are not desired, a set screw can effectively fasten the components together without interfering with the operations.

A set screw can be identified with its signature headless body. The entire body of the fastener is threaded and it comes in various dimensions. To securely fasten the set screw in place, a special internal wrenching drive or an Allen key is used. Once the components are fastened, the set screw exerts a clamping force in order to secure the components in place.

Types of set screws

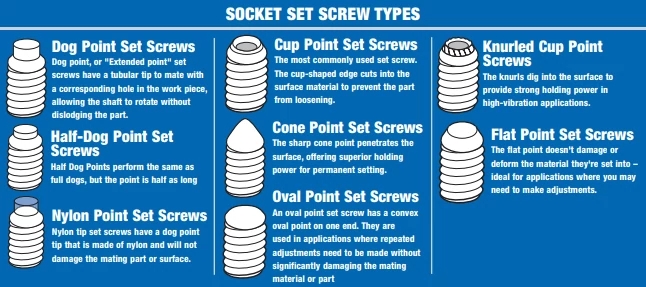

Set screws have different point types based on the characteristics required out of them. A few examples of its point types are, plain cup, knurled cup, flat, oval, cone, half dog, and soft tipped.

Here are a few pros and cons of the different types of set screws.

| Plain cup | Knurled Cup | Flat | Oval | Cone | Half-dog | Soft-tipped | Nylon tip | Brass tip | |

|---|---|---|---|---|---|---|---|---|---|

| Permanent hold | yes | yes | yes | yes | yes | yes | |||

| High compression force | yes | ||||||||

| Vibration-resistance | yes | ||||||||

| Reusable without damage to threads and surface | yes | yes | yes | ||||||

| Fits well with holes | yes | ||||||||

| Fits well with grooves | yes | yes | |||||||

| Can be used as adjusting screw | yes | yes | |||||||

| Can be used as hanger points | yes | ||||||||

| Can be used on soft metal | yes | yes | yes | ||||||

| Can be used on both hard and soft materials | yes | yes | yes | yes | yes | ||||

| Can be used at any angle | yes | yes |

Set Screws Head-types:

Straight slot:

A straight-slotted set screw, as the name suggests, can be used with a flat screw driver to be inserted and removed. Very little torque is required to keep this in place but it mostly finds its use in very simple applications.

Hex socket:

The head of the set screw comes with a hex recess and requires a special hex wrench or Allen key to be used on it. It is often tamper-resistance and can be used with more complex requirements.

Square socket:

A square socket set screw, also known as Robertson or scrulox screw drive, comes with a square protrusion on the tool. The tool as well as the socket come with tapers which makes the installation of the fastener very easy.

External hex:

With the external hex screw drive, a six sided tool or a special wrench with a combination or adjustable point sockets has to be used. This head type is preferred over the square socket in places which has restrictive space surrounding the set screw.

External Square:

This requires a four sided adjustable wrench or an open ended wrench to be used on it for any operation.

Bristol Spline:

This set screw comes with four or six splines at the head. However, this does not make the fasteners tamper-resistant. The grooves are cut using a square-cornered broach, giving the outer corners of the drivers a slight undercut. Once the torque is applied in the right direction, the possibility of splitting the fastener is completely eliminated.

At ITA Fasteners, we don’t restrict ourselves to only the most widely used fasteners. We are specialised manufacturers of even the rarest fasteners like the set screws. Our excellent reputation has been built upon having everything our clients need, even if it is one of the rarest fasteners available in the market. In addition to this, we also manufacture and stock socket set screws of various materials and dimensions. If you’ve got a specific requirement, we’d love to hear about it and help you out. Get in touch with us at sales@itafasteners.com to know more.

ITA Fasteners Back